Differential Airshafts

Differential Airshafts

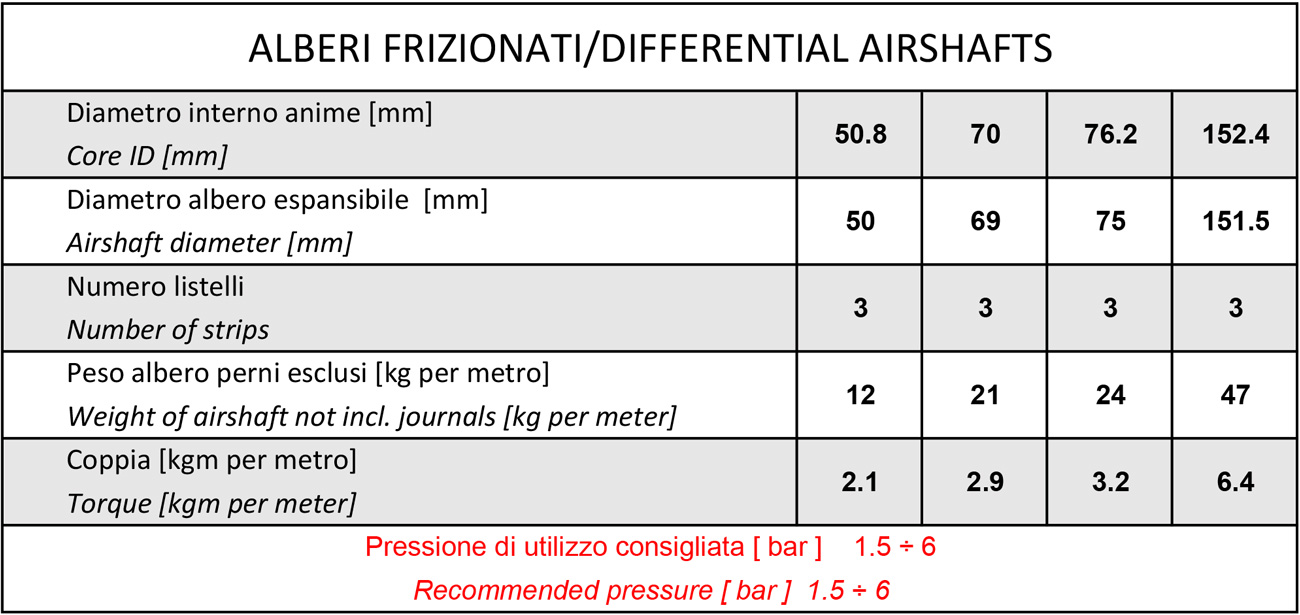

They are designed to rewind multiple rolls (even having different diameters) with cardboard cores. Differences in material thickness may often arise when rewinding plastic films and other materials.

These variations can result in considerably different diameters of rolls, especially if they are narrow; in this case the winding torque required is slightly different. Actually some rolls may be too tight, while others not enough after only a few rewinding rotations, with a consequent reduction of the end-product quality.

Our differential airshafts ensure the highest winding quality even with narrow rolls. By maintaining the proper tension on all rolls throughout the winding cycle, the web material will no more show any inconvenience.

The friction rings and the single rolls slip continuously on the underlying central body; thanks to the different slipping speed a uniform tension value is ensured. A rotary union allows constant air feeding to control the air pressure in the bladders and the web tension according to the different roll diameters.

- The central body can be made of ground and chromed steel or hard anodized aluminium.

- Polyethylene, polyurethane and felt friction strips are available to suit the max. tension required.

- All zinc-plated steel journals are manufactured according to customer’s drawing

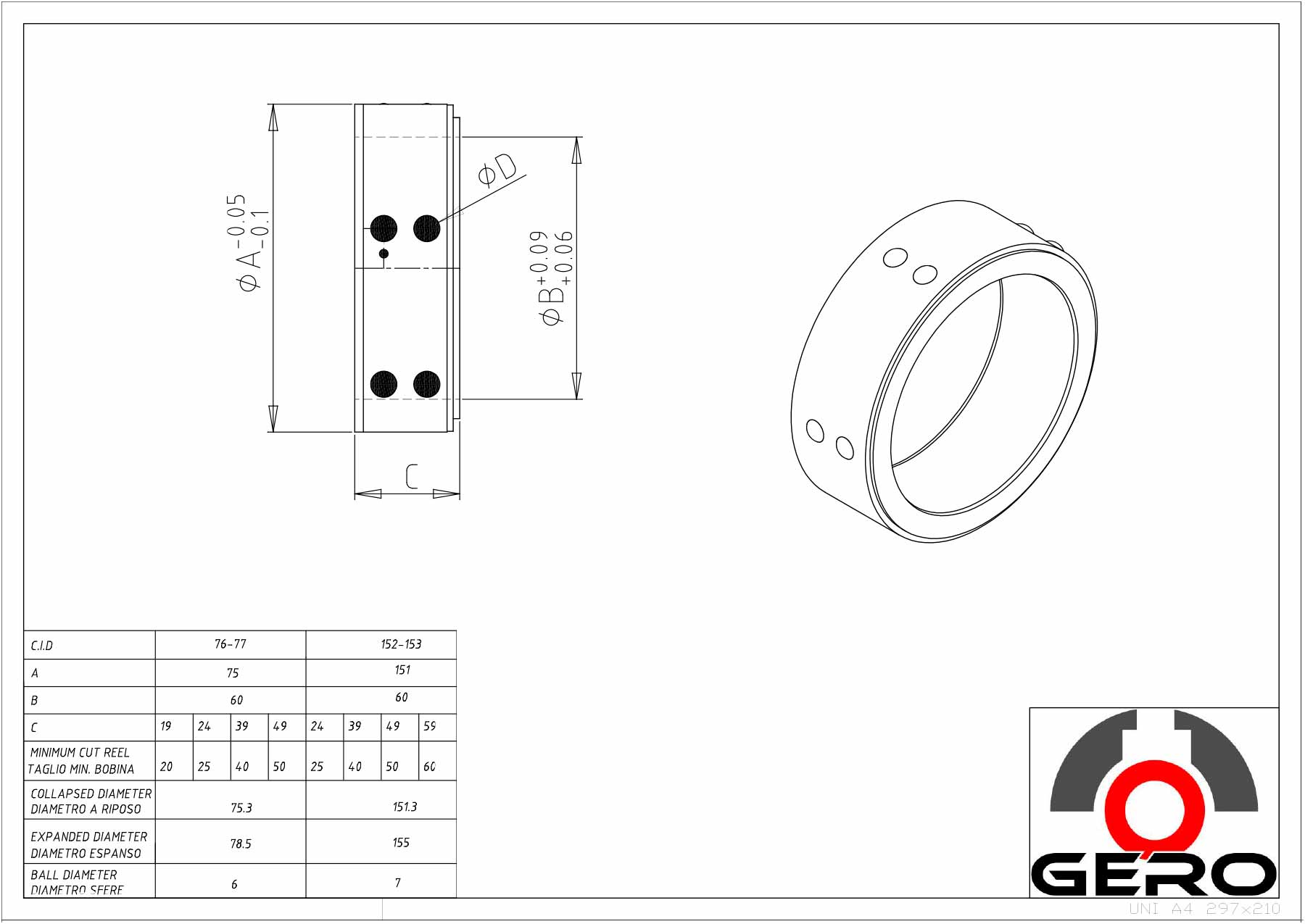

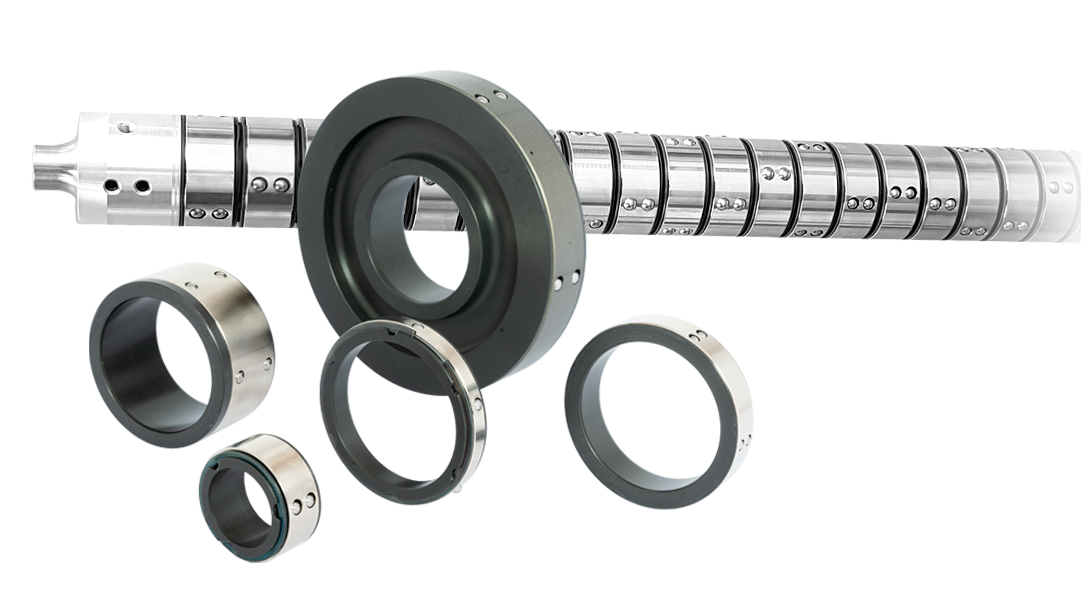

Up&Down friction rings

A special design of friction rings was developed to improve the performance of our differential airshafts. The result is an innovative high quality product.

Thanks to our new UP&DOWN friction rings the cores can be inserted when the shaft is not rotating, without having to counter-rotate it. In case of manual insertion there will be no risk of shock for the operator’s hand.

- After rewinding, when the rings are stationary, rolls can be extracted without having to counter-rotate the shaft.

- Rings can be used with cardboard, plastic or metal cores (min. ID 40 mm – 10 mm wide)

- High quality material with anti-wearing and anti-oxidation treatments

- From minimum width of 15 mm, corresponding to the size of the roll, the rings allow perfect blocking thanks to their both inline balls

- The minimum compression of the spring will reduce its wearing over the time

- The shape of slots in the upper ring will protect from dust and can even allow its ejection